By Maggie LaNoue

Contributing Writer

June 27, 2025

Just west of Marshall, Michigan, and south of I-94, a massive factory is rising — BlueOval Battery Park Michigan. On a hot June morning, journalists from across the country gathered for what may be the only media tour of the site before it becomes an ultra-clean, dust-controlled zone for battery production. This was an exclusive opportunity made possible by the timing: the building structure is nearly complete, but the delicate equipment has not yet arrived.

Even before stepping inside, the scale of the project was clear. Thousands of construction worker vehicles surrounded the site, and more than one journalist briefly got off track before being guided to the northeast corner entrance.

There was some dust along the drive, but the sky above was a rare, brilliant blue — a welcome sight in Michigan, where many days are overcast or hazy with humidity, and sometimes even touched by Canadian wildfire smoke. Security personnel were stationed at key access points to guide journalists to the temporary office on the northeast corner of the site.

There, in a temporary office building, was housed the day’s Media Event. Inside, everything was in place: bottled water, coffee, high-visibility vests, and hard hats laid out on a long table. Fewer than twenty journalists—some with laptops, one with a clipboard—took their seats in a modest, well-organized meeting room. Behind them, three TV cameras were stationed. Reporters from the Wall Street Journal, New York Times, Bloomberg, Crain’s Detroit, Axios, the Marshall Advisor & Chronicle, and local TV stations all attended.

Some local Ford employees, including Albion’s own Leslie Spicer Williams, Talent Acquisition Manager, and Scott Kipp, Security Team Lead, are already working at the site—a point of pride for area residents. Williams, who grew up in Albion as the daughter of Joyce Spicer, said, “We find good people in all communities.” Kipp added, “These are good-paying jobs,” reflecting on the opportunity this project represents for the region. A link to job listings is included below.

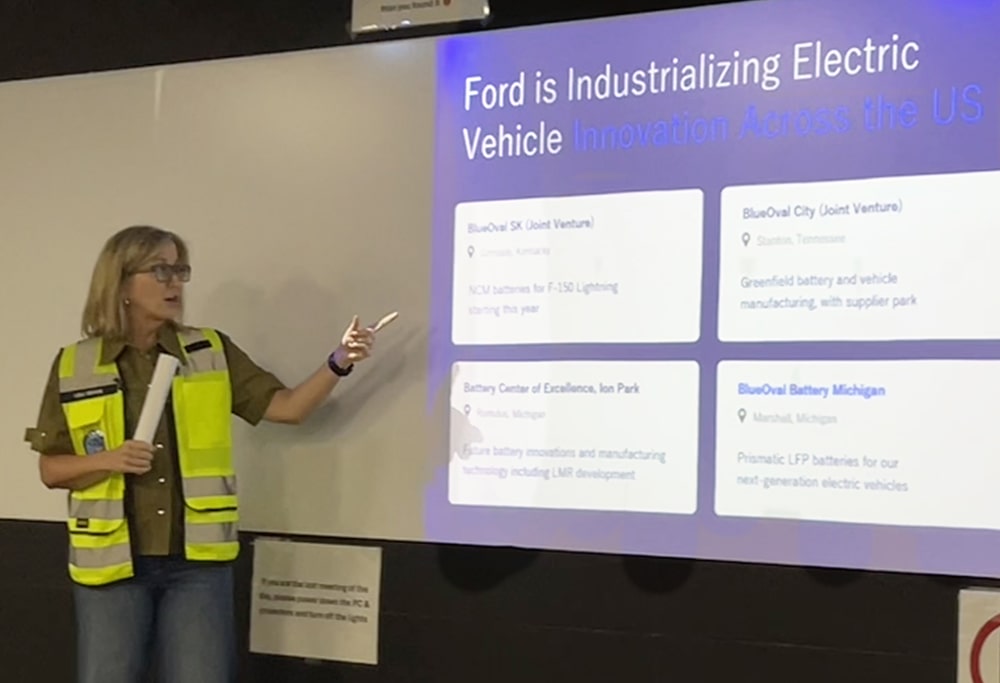

Lisa Drake, Ford’s Chief Operating Officer for Electric Vehicles, opened the media session by highlighting the deeper strategy behind the Marshall battery plant. Instead of pouring hundreds of millions more into R&D, Ford chose to invest in large-scale American manufacturing—its core strength. She called the Marshall facility a model for future plants, especially those aiming to scale up electric vehicle battery production using proven technology and local talent.

The decision to license lithium iron phosphate (LFP) battery technology from CATL wasn’t a step backward, Drake said, but a way to accelerate production while creating high-tech jobs in Michigan. The technology, she reminded the group, originated in U.S. research labs decades ago but was commercialized overseas. Now, Ford is bringing it back—and building the systems and workforce to match.

Drake explained the broader strategy during the media tour. “The equipment is on boats coming over from China and going into a large warehouse. It will be all Ford equipment. In this tariff environment, it is better to pay tariffs on the equipment and make the cells here. We will have full control of the production.”

Drake described how the facility’s design is being built around the production equipment itself. “You don’t just build a building and roll in the machinery,” she said. “The machinery designs the building.” Every step, from the layout to the floor plan, was shaped by the requirements of the equipment now on its way to Marshall. Ford has already mapped out the installation process, starting with prototypes and integrating three different types of battery chemistries across its EV lineup—a global first.

After the talk concluded, filming gear was packed away—cameras were not allowed inside the facility. From that point on, the story would unfold through observation: boots on the ground, notebooks in hand. Journalists were asked to wear closed-toe, ankle-covering footwear before boarding vans—one for local media and another for state and national reporters. The bus traveled on an oblong road that went around the entire building, in part, to keep vehicles further away from the workplace and to keep any dust away from the entry areas. The first stop was the far west end of the mile-long building, known as the back end, where completed battery packs will eventually be staged for shipment. Although rail lines are not yet in place, plans exist to add them if needed. The building is zoned from east to west, with raw materials entering at the east and finished products exiting at the west. Each area is engineered to limit contamination, and a central corridor called “the spine” runs the full length of the facility, designed for automated guided vehicles (AGVs) to transport materials from east to west.

Inside, rooms are already designated for the anode and cathode processes—essential steps in creating electric vehicle batteries. The next tour stop was the central employee entrance on the south side of the building. From here, production staff will enter locker rooms to shower and change into cleanroom gear, while support staff will head upstairs. This hub will include a restaurant, break room, and a dramatic staircase leading to offices and mezzanine-level utility rooms. Journalists climbed three flights to view this upper level, where modular racks for electric, water, and hot oil lines—assembled off-site—were already in place, emphasizing efficiency and protection from Michigan’s winter weather.

Ford representatives explained that different areas of the plant will transition in stages to “clean room” status as it prepares for C-sample production—the final prototype phase before mass manufacturing begins. This facility, fully owned and operated by Ford, will be the company’s first to produce prismatic lithium iron phosphate (LFP) batteries at scale.

These prismatic cells, named for their rectangular shape, differ from the cylindrical type used in earlier batteries. Their flat structure allows them to be tightly stacked, improving space efficiency in electric vehicles. LFP chemistry offers advantages such as thermal stability, long cycle life, and simplified pack design—making them a safe and affordable choice for mass-market EVs.

Ford’s investment in Marshall reflects a strategic move to localize the production of this next-generation battery format using technology licensed from China’s CATL. By building LFP batteries in Michigan, Ford hopes to reduce costs, stabilize its supply chain, and accelerate the delivery of affordable EVs to the American market.

A key uncertainty shadowing the plant is a sweeping federal budget bill officially titled the “One Big Beautiful Bill Act,” which, if passed, would eliminate key clean-energy incentives before their current expiration date. Among them: the $7,500 federal tax credit for new electric vehicles and a $4,000 credit for used EVs—set to sunset December 31, 2025, instead of under the existing law through 2032.

Industry voices warn that the rollback could sap momentum at major EV manufacturing hubs. A Senate analysis noted that accelerating the phase‑out risks undercutting investment and consumer demand. For Ford, which is building its Michigan battery plant around LFP battery production, these tax credits have been a crucial part of the economic justification. The automaker has insisted it will continue regardless—but warns that removing subsidies could imperil the plant’s cost-competitiveness.

Additionally, the bill proposes new annual fees on EV owners—$250 for electric and $100 for hybrids—to fund road infrastructure, a move consumer advocates say contradicts the goal of promoting sustainable transportation.

This political backdrop—budget fights in Washington, shifting incentives, and scrutiny of foreign-licensed battery tech—adds tension to the day’s message of progress and local pride. As Ford executives push for American jobs, they’re navigating a legislative landscape that could reshape the industry’s financial foundation.

The Ford Blue Oval Plant is more than a place to manufacture key components to electronic vehicles. It is a model for future plants, and the best way to get feedback to fine-tune the operation is to get it running.

At a meeting spot outside near the end of the tour, BlueOval CEO Scott Davis answered questions from journalists. “Ford has invested three billion dollars in the Marshall plant. The job pay and benefits will be competitive to the local market. It is not a union plant since there is no hired production team. It is up to them — the people can decide.”

Although BlueOval Battery Park Michigan won’t begin producing batteries until 2026, this may be an ideal window of time for consumers to consider purchasing an electric vehicle. Not only are the federal EV tax credits still in place—for now—but Ford is also offering employee pricing to all customers through July 4, 2025. That deadline falls just one week after this article’s publication.

The message to consumers? Whether or not the “Big Beautiful Bill” advances through Congress, there’s still time—at least for now—to benefit from the current incentive structure.

A Model for the Future

Ford leaders described the Marshall facility as a model for future battery plants. Rather than simply building a structure to house equipment, the layout was engineered from the ground up to support clean manufacturing and operational efficiency. This forward-thinking approach could influence the design of other Ford battery production facilities in the years ahead.

The battery plant represents a major investment in the future of both Ford and Calhoun County. Whether it becomes a national model or another flashpoint in Marshall’s long civic history remains to be seen. But the project’s scale—and the conversations around it—are too large to ignore.

Notes:

Lisa Drake, *From the Road* (May 29, 2025) “American Battery Plant Helps Power the Future of Electric Vehicles,”

https://www.fromtheroad.ford.com/us/en/articles/2025/ford-owned-american-battery-plant-future-electric-vehicles

Ford, *From the Road* (April 25, 2025)“Ignore the Rumors: Money Still on the Table for Electric Vehicles,”

https://www.fromtheroad.ford.com/us/en/articles/2025/ignore-the-rumors-money-still-on-the-table-for-electric-vehicles

Jobs at Blue Oval Marshall:

https://www.careers.ford.com/en/locations/north-america/campaign-blueoval-battery-park-marshall-michigan.html

Employee pricing to all

https://www.fromtheroad.ford.com/us/en/articles/2025/ford-employee-pricing-through-fourth-of-july

Share this post with your friends or on your other social media by clicking one of the icons below: